Yaskawa Export Support Now Available

As part of our ongoing effort to enhance our software, we are pleased to introduce a key new feature: export support for Yaskawa robotic applications. This functionality allows users to seamlessly a...

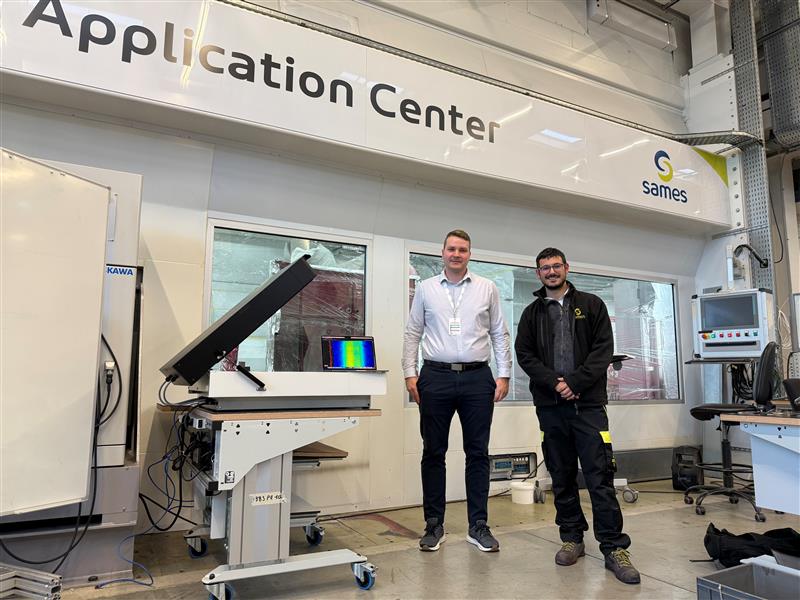

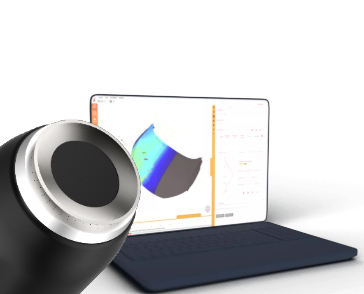

We’re happy to share that we have successfully installed the latest version of our SprayCapture Mk. II at Sames, Meylan. Technology will be used in their Application Center for customer trials and validations.

The new version of hardware has higher level of sensors and improved light possibilities to better analyse even highly opaque paints.

Sames will use this technology to identify and verify settings faster, making customer trials more efficient. Another benefit is presenting results to customers in data-supported form.

We have also discussed with the Sames management team how to use our SprayBrush to speed up implementations of latest technologies for Sames’ atomizers.

For more insights, follow us on LinkedIn.